Passive House Wall Panels

At the end its the u value that counts and it can be achieved in a lot of different ways.

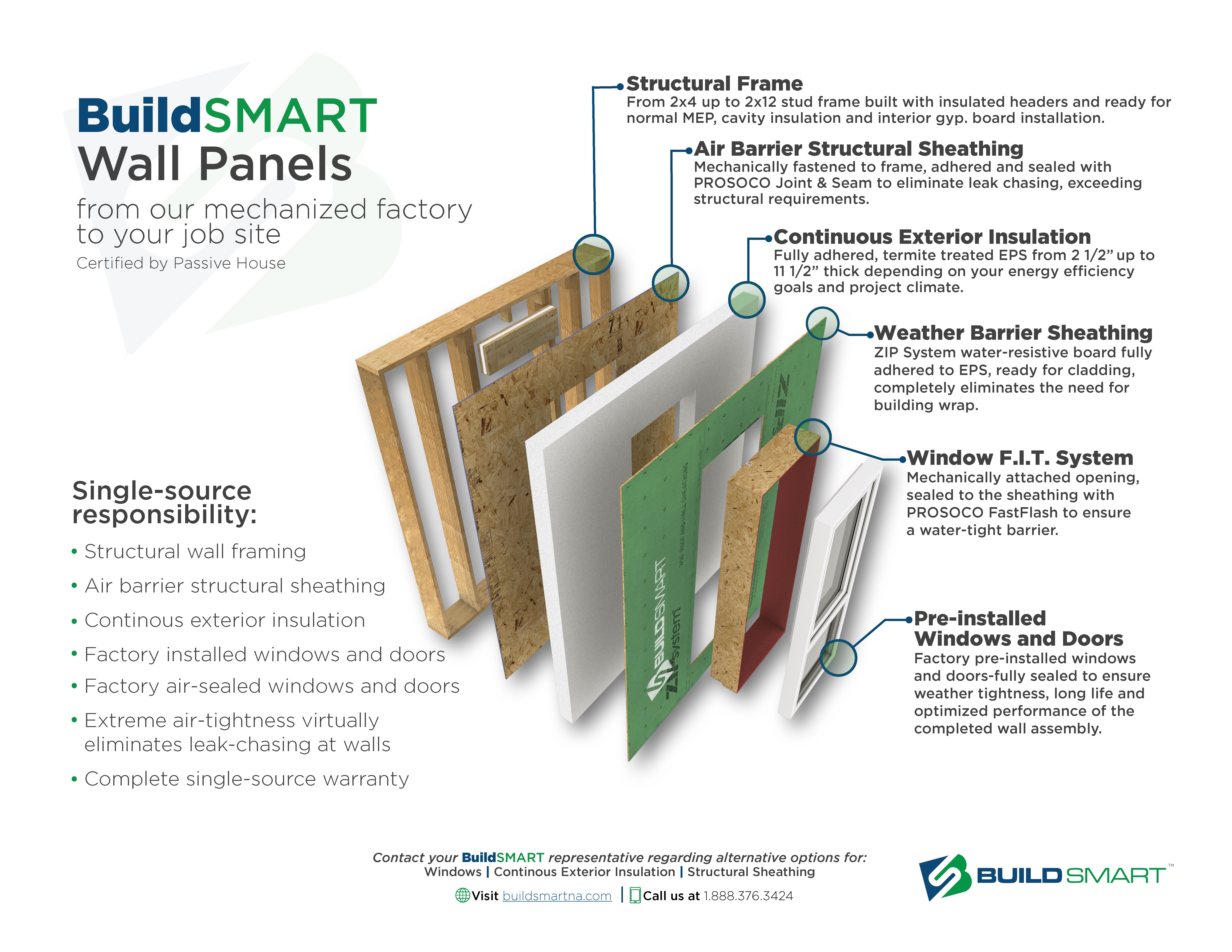

Passive house wall panels. All components are engineered with virtual models before construction starts eliminating potential issues guaranteeing a high quality and consistent assembly every time. Nine foot panels were selected for this project. The build smart building envelope system ensures air tight energy. The sub trades can drill holes through those studs without compromising the air tightness and insulation of the sip panels both of which are critical in a passive house.

Diffusion board open to outside. Panels can meet passive house and net zero standards for high performance building. Build smart manufactures multifamily and single family wall assemblies and foundation insulation systems to the highest standards of energy efficient design. Passive house lessons from the northwest.

Highly energy efficient multifamily and single family buildings are made simple and affordable with build smart systems that incorporate prosoco sealing products. Green r panel is the industry leader custom home builders and do it yourselfers depend on for fast trouble free prefab erection systems. Leveraging their experience with stick built passive homes companies including bensonwood buildsmart ecocor and threshold builders have panelized the building envelope producing passive. Phlex pronounced flex is a new product and concept that provides a cost effective precise and high quality assembly of building panels walls floors and roofs to achieve customized passive house performance.

As for the wall section r52 from the exterior to the interior the prefab panel has. Osb sheathing taped and sealed with service wall. Pre numbered wall panel roof truss and floor truss or i joist if required systems are delivered to the jobsite flat packed ready to assemble. The interior seams of the sip panels will be taped with a product designed for that purpose not the red tapes used for detailing vapour barriers and house wrap.

Bensonwood has launched a new product designed for the growing passive house industry. Bc passive house in canada has a manufacturing plant that s making these panels and i thought it would be interesting to share what s inside the company s next gen high performance panels. September 4 2014 by sam hagerman. Once the floor framing and decking was installed a prefabricated rim joist panel was installed and sealed between panels.

2 8 studs or higher per phpp. The phlex panels are designed to meet or exceed passive house standards a rigorous standard initially developed in germany resulting in superior energy efficiency and an ultra low carbon. The insulation thickness of the eifs as a rule is between 150 and 300 mm in a passive house but can be bonded as single layer up to 400 mm. This paper published as part of the 9th annual north american passive house conference next week shares the evolution of hammer hand s wood framed passive house envelopes in the pacific northwest.

4 years 5 walls 6 projects.