Process Cooling Water Pressure

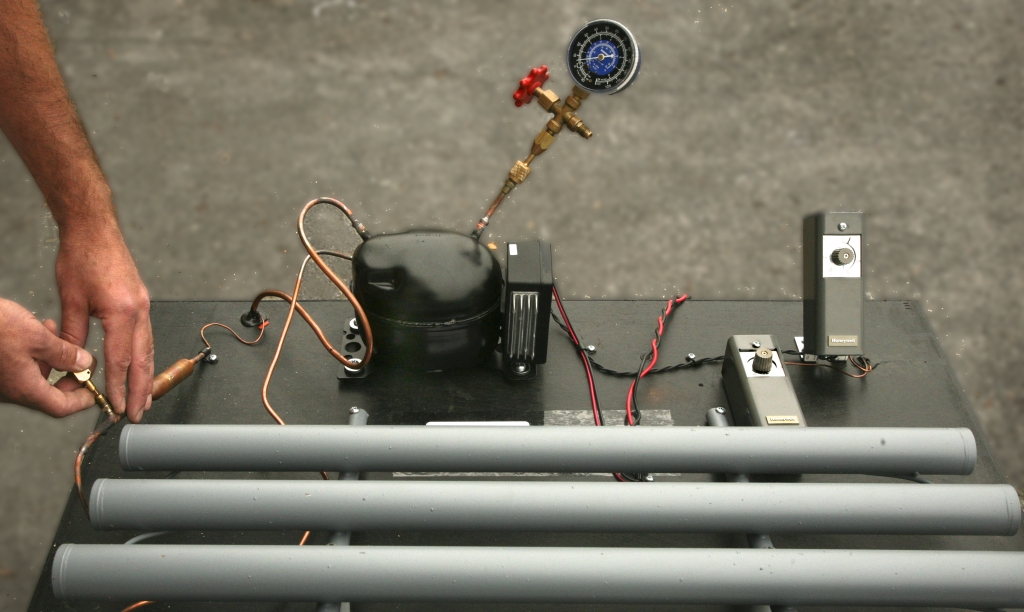

S s technical is a leading manufacturer of pcw process chilled water systems for multiple industries.

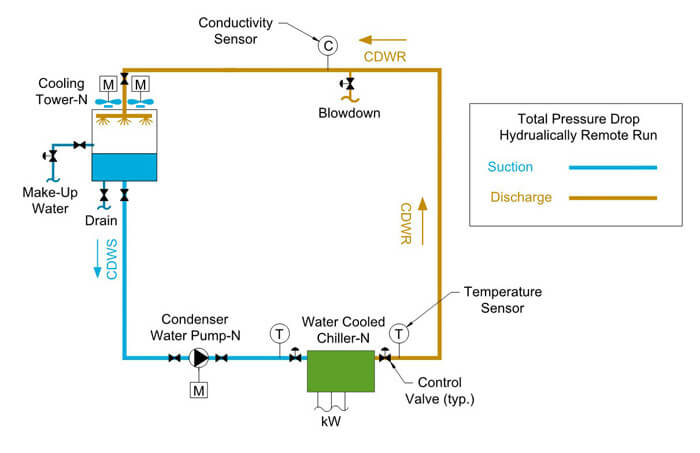

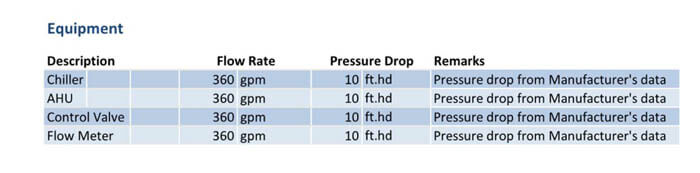

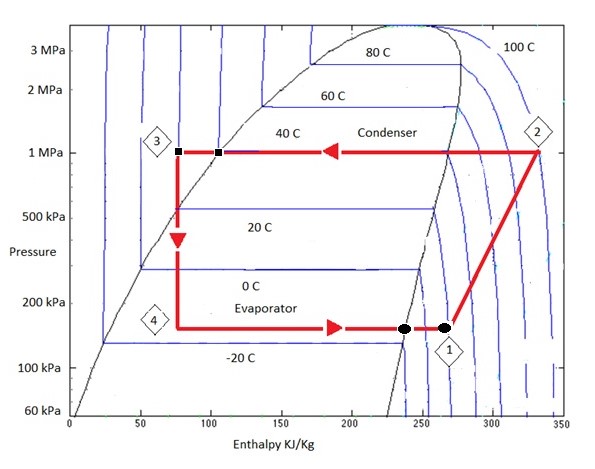

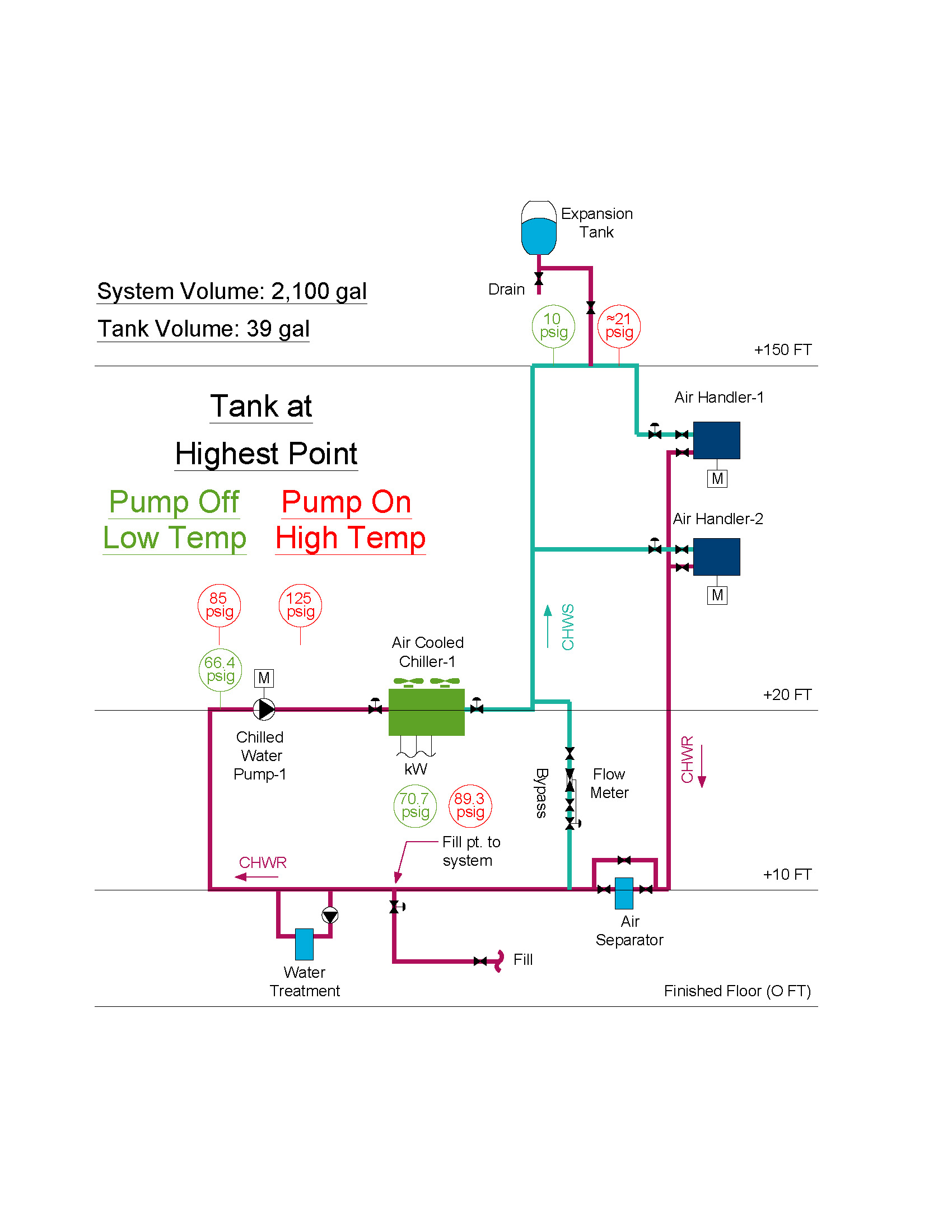

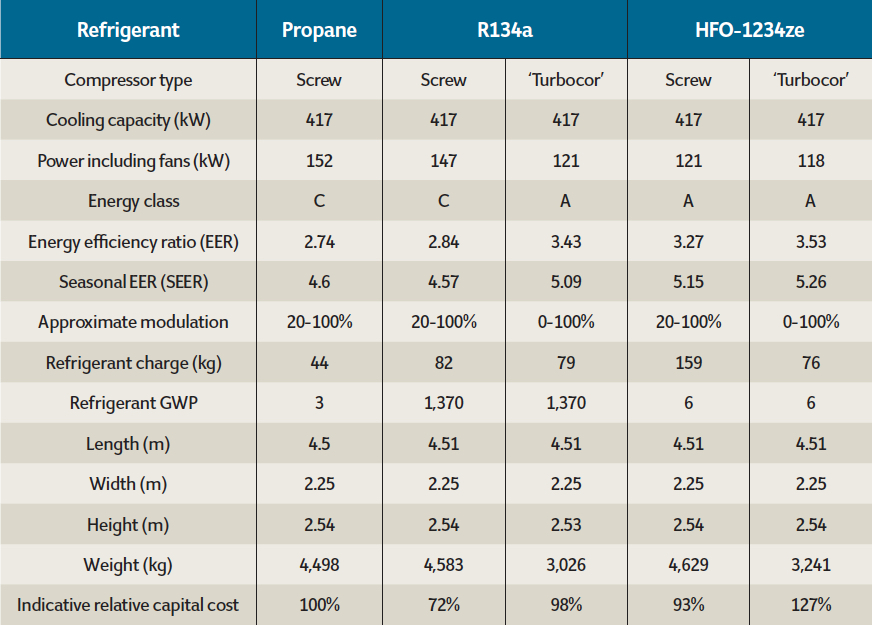

Process cooling water pressure. Improving cooling system reliability with filtration cooling water corrosion control choosing a water filtration system new products and much more. The first factor that should be considered is the maximum pressure that the cooling system is going to have to hold to determine the. Cooling water systems are used in many industries to remove waste heat from the process to the environment. The valve pressure temperature rating must be within the system design parameters.

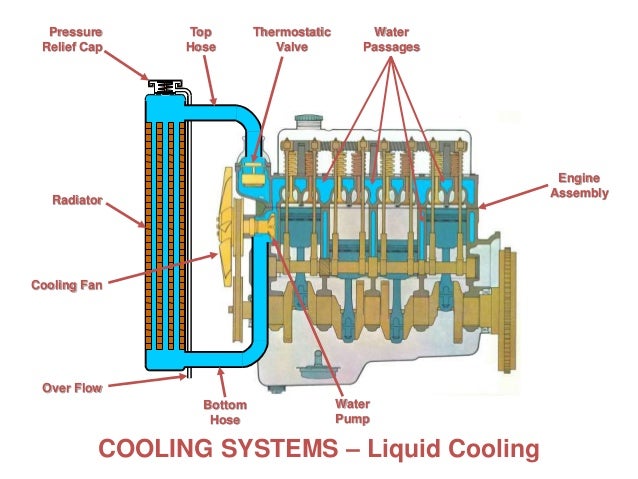

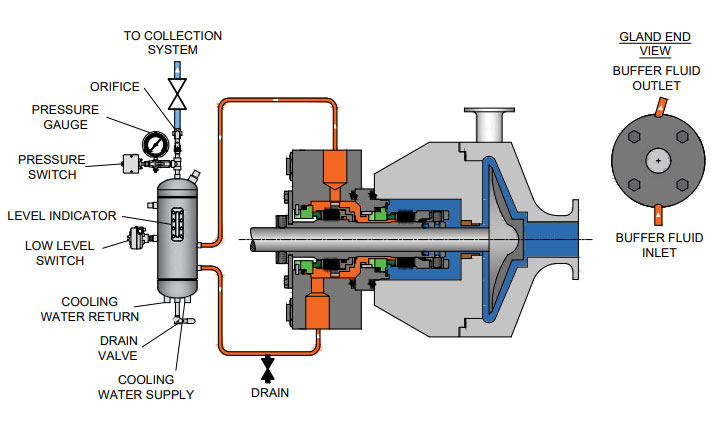

Water may be a more efficient heat transfer fluid where air cooling is ineffective. Cooling water is usually circulated between process heat exchangers and a cooling tower. Gololo thokozani majozi in computer aided chemical engineering 2012. Pcw packages are skid mounted systems that circulate process or cooling water at a specific temperature and pressure.

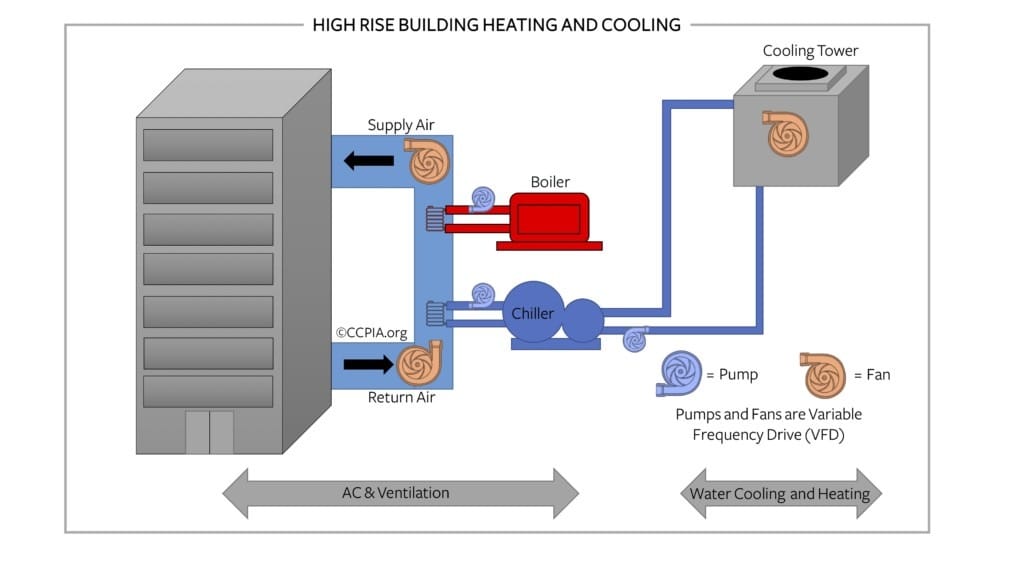

Low cost often allows rejection as waste after a single use. Process cooling water systems. Process chilled water systems pcw are compact skid mounted systems that circulate process water at a consistent temperature and pressure to the application s point of use and back allowing for more efficient and stable use of water cooled machines equipment and instruments. Under the pressure of ongoing steam generation steam fills the void in the miles of underground supply mains leading to buildings across campus without the need of being pumped.

In most occupied climates water offers the thermal conductivity advantages of a liquid with unusually high specific heat capacity and the option of evaporative cooling. Check out the september 15 2020 edition of process cooling. This enables water cooled machines and equipment to operate more efficiently and stable. Water cooling is a method of heat removal from components and industrial equipment.

In our boilers steam is produced at very high pressure with more heat content very much like a residential pressure cooker. The most cost effective and energy efficient process cooling water systems custom engineered designs to meet specific system requirements for use in any process cooling application such as plastics molding chemical process mining and deionized or high resistivity fluid factory hydrostatic and operation testing prior to shipment. Research in this area has focused mostly on optimization and synthesis of cooling water systems in which the technique of recycle and reuse is explored.